Until the end of the nineteenth century, the most important source of nitrogen was natural organic materials, but mineral sources were also important. Of these, by far the most significant were the sodium nitrate deposits in Chile, providing some 70 per cent of the world supply. By the 1960s this figure had shrunk to 1–2 per cent. The reason for the decline was the successful tapping of the richest source of nitrogen of all: the air we breathe. The ‘fixation’, or chemical combination, of nitrogen was known to be chemically feasible by the end of the eighteenth century and from around 1900 several processes had been developed on an industrial scale. But by far the most important of these was that worked out by Fritz Haber.

It consisted of the synthesis of ammonia from its two constituent elements, nitrogen and hydrogen. The reaction had been studied spasmodically for many years but it was Haber who transformed it into anindustrial proposition. High pressures were at first avoided, but Haber found during his researches from 1907 to 1910 that a pressure of 200 atmospheres produced the highest yield. At that stage BASF once again entered the scene and engaged in research to find the most suitable catalyst. In 1913 the first full-scale plant for the synthesis of ammonia by the Haber process was built at Oppau, with a second at Leuna, near Leipzig three years later. By 1918, the process contributed half of Germany’s output of nitrogen compounds.

Hostilities with Germany hindered the spread of knowledge of the process and it was only in the 1920s that manufacturing plants were set up in other leading industrial countries. Progress was then rapid and by 1950 fourfifths of nitrogen fixation was by this process.

The catalyst most widely used from 1930 was finely divided iron mixed with various oxides. Nitrogen fixation became important not only for the production of ammonium sulphate and nitrate fertilizers but for the manufacture of nitric acid, much in demand before and during the wars for making explosives.

As to phosphorus, the main source until around 1900 was ground bones or bone meal, but in the last decades of the nineteenth century large deposits of calcium phosphate were discovered in northern Africa and, later, other major producers were the USA, USSR and the Pacific island of Nauru. The calcium phospate is converted to ‘superphosphate’ by treatment with sulphuric acid, first achieved on a large scale from 1834 by John Bennet Lawes at Rothamsted in Hertfordshire. ‘Triple superphosphate’, or monocalcium phosphate produced by treating the mineral form with phosphoric acid, attained equal importance with the ‘super’ variety in the USA in the 1960s.

Potassium fertilizers (potash), mainly potassium chloride, have been applied as they were mined, the Stassfurt region in Saxony being the leading source for some 130 years.

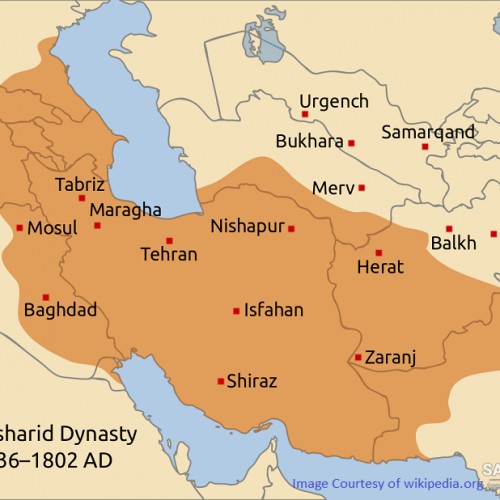

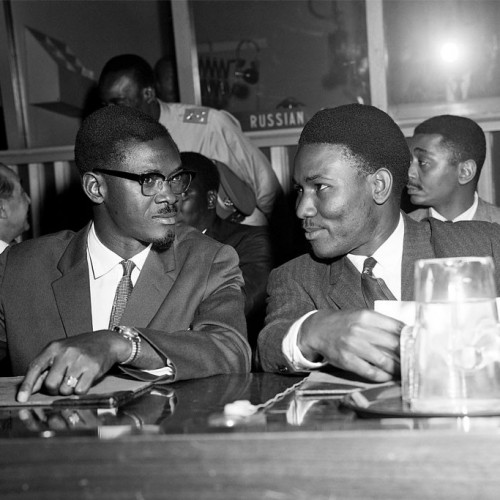

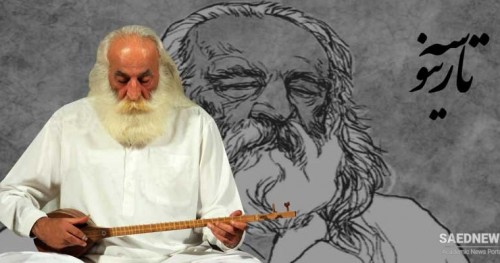

Abu-Abdullah Muhammad ibn Isa Al-Mahani

Abu-Abdullah Muhammad ibn Isa Al-Mahani