Metal workers were a class of specialists who needed specialist equipment and who depended for their sustenance on the labours of their fellow men, the farming community for whom they provided the tools. Many ancillary trades, too, were involved, in the quarrying or mining of the ores to be smelted. The construction of furnaces and the manufacture of crucibles were to become other objects of specialization.

The human lungs and the blowpipe produced a very limited area of high temperature for smelting, so that the blowpipe was virtually restricted to goldsmiths. Around 3000 BC bellows were developed, at first from the whole skins of sheep, goats or pigs, or from clay or wooden pots topped with a flexible membrane of leather. Copper ore was not to be found in sufficient quantity in the ‘fertile crescent’ where it was first used. Thus traders and carriers were required using, at first, pack animals and later wheeled vehicles, then riverboats and sea-going ships. All these called for further specialists to produce them. These in turn needed further tools with which to work and added to the number of specialists who had to be fed.

It has been suggested that copper ore was mined at Mount Sinai as early as 5000 BC and 2000 years later in Oman in the south of Arabia. These are respectively some 1400 and 2000km (875–1250 miles) from Mesopotamia, a long haul for the unrefined ore and a powerful incentive towards the invention of the wheel. It was about 3500 BC that the wheel was first added to a primitive sledge at Erech in Sumeria. Strictly speaking, the invention consisted more of the axle to which the wheel was fixed, for previously wheel-like rollers had been placed beneath the sledges, especially when heavy loads were involved.

Some of the heaviest of these were the great obelisks, a characteristic of Egyptian civilization, which were as much as 500 tonnes in weight and 37m (122ft) h1gh when erected. They were quarried in the horizontal position, in one piece, from around 1470 BC. It is believed that the huge blocks were cut out of the parent granite by continual pounding from a round stone of dolerite so as to generate a narrow trench all round; the final undercutting to separate the obelisk must have been an awesome task. Apart from the glory brought to the name of the pharaoh who had ordered the obelisk, it had little use except as the gnomen of a sundial.

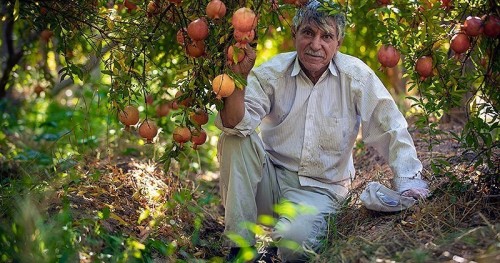

The plough was a vital invention for a civilization that was becoming increasingly dependent on agriculture, and a great improvement on the hoe as an instrument for tilling. An intermediate device, which survived in the Hebrides until the nineteenth century as the caschrom, was the lightweight man-plough and it was not until about 3000 BC that animals started to be harnessed to the plough or the cart. In warfare, horses were at first used to draw two-wheeled chariots: men did not learn to ride horses until about 2000 BC and the saddle is a much later invention which did not become truly effective until stirrups were added, allowing the horseman a better purchase with sword or spear.

There has always been a need to join one piece of material to another, be it wood, leather or metal, or to join wood to stone as in the hafted axe. Thongs and cords or ropes of fibres woven together served at first, but both the nail and the rivet were known to the coppersmiths of Egypt well before 2500 BC. Such nails were used in sailing ships some five centuries before that date. These again were Egyptian and represent the first known application of a natural source of power other than animal power, the wind. The use of wind power to drive the rotating sails of a windmill does not appear to have occurred for another three millennia or more.

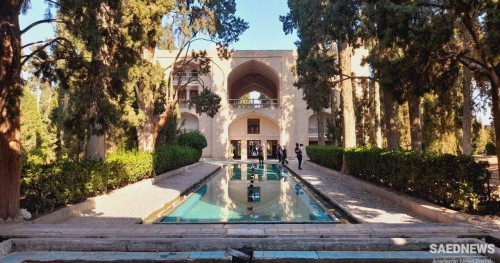

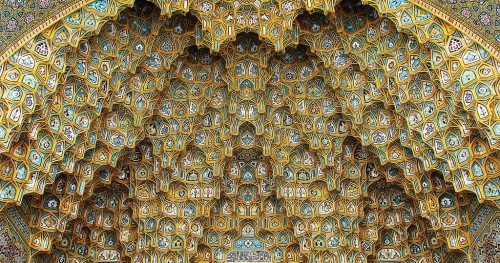

Civilizational Roots of Technology: Rise of History and Advanced Life

Civilizational Roots of Technology: Rise of History and Advanced Life