Owing to its density and hardness, stone was probably the most popular material for tools in the Stone Age. Thanks to its durability, it is also the most common material of such tools as have survived the centuries since they were in use. The oldest and, at the same time, the most primitive that are undoubtedly man-made, or made by his predecessors, are the pebble tools found by Richard Leakey in Kenya which have been dated at 2.6 million years old. These include the characteristic core and flake tools; the flakes produced as waste in the process of developing the core were put to good use, as many of them had sharp cutting edges. Characteristically such core pebble tools were only flaked to produce a sharp edge at one end. It is notable that in this, the world’s oldest industry, dating back probably some 5 million years, ‘tools to make tools’ were included, hammerstones and anvil stones being found in the lowest levels at Olduvai in Tanzania.

So-called hand axes, on the other hand, were bifaced, that is to say, sharpened by flaking all round the periphery. The development of this type of tool is also attributed to peoples in Central Africa, supposedly dating from about half a million years ago. This was a general purpose tool, serving not only as an axe but also for piercing and scraping the hides of animals. Not only pebbles were used in their manufacture: some show signs of having been quarried from the natural rock.

Where long parallel-sided flakes were produced, usually from flint, chert or obsidian, they represent the so-called blade-tool industries. From these basic knife blades a number of variants have been found: gravers, spokeshaves, saw blades, planes and drills have been identified by palaeontologists, although the common man might have some difficulty in distinguishing some of them. All belong to the Upper Palaeolithic period that is, say, from 35,000 to about 13,000 years ago when hunting was still the primary source of food.

The Mesolithic, or Middle Stone Age, lasting approximately from 12,000 to 7000 BC, saw a revolution in the making of stone tools. The techniques of grinding and polishing, already applied to bone and ivory in Middle and Upper Palaeolithic times, began to be used for the surfacing of stone tools. An axe with a smooth surface would be much easier to use for felling trees, though its advantages with some other types of tool do not seem to be so evident. Basalt and epidiorite, finer grained igneous rocks, are more easily ground and polished than flint and it is supposed that the technique probably originated in regions where these rocks were in common use for tool-making. This grinding and polishing was probably at its peak around 6000 to 5000 BC, declining in importance after 3000 BC when copper and then bronze came into use.

The grinding and polishing process generally involved rubbing the tool against a slab of wetted sandstone or similar hard rock, sand being used as an abrasive powder if only a non-friable rock was available as a grinding base. Some axes of the Neolithic and Bronze Ages, probably used for ceremonial purposes, have a very high polish suggestive of a final burnishing with skins and a polishing powder. These have generally been found associated with the burials of tribal chieftains.

The production of the basic core and flake tools was a skilled occupation using one of two methods—pressure flaking or percussion flaking. In the former, a tool of bone, stone or even wood was pressed against the core so as to split off a flake and the process was repeated. In percussion flaking a hammer stone was repeatedly struck against the core or against an intermediate bone or wooden tool applied to its edge. Either process requires a high degree of skill, acquired through long practice and much experience and, in the case of the more complex shapes such as barbed and tanged arrowheads, indicates a degree of specialization at an early date.

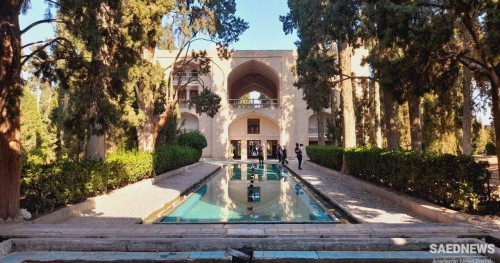

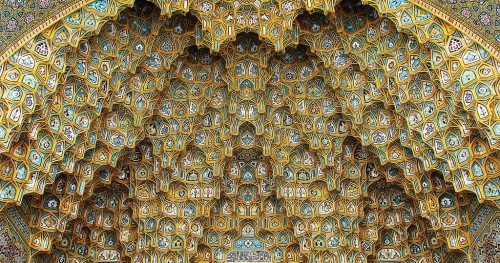

Optimum Use of Water Supplies, New Irrigation Technologies and Sustainable Farming

Optimum Use of Water Supplies, New Irrigation Technologies and Sustainable Farming