The mechanical, weathering and electrical properties of porcelain made it an ideal material for insulators and resistors, still largely made from ceramics. In the 1850s bell-shaped insulators for telegraph poles came into use throughout the world. In the chemical industry, ceramic-lined vessels became a necessity for certain processes and to contain such materials as acids: chemical stoneware is resistant to cold acids, except hydrofluoric, and most hot acids.

Progress in the metallurgical industries could not go far without improving on the crude clay-lined furnaces of earlier times. From 1860, Austrian magnesite bricks came into wide use for iron and the new steelmaking furnaces. An understanding of the acid or alkaline nature of refractory furnace linings was crucial to the success of the Bessemer steelmaking converter. When the outbreak of the First World War interrupted the supply of magnesite, the drawbacks in the use of the cheaper dolomite were overcome.

The effect of mechanization in raising output has already been mentioned. A further boost was provided by improvements in kiln design. Efforts were first made to economize in fuel consumption and to cut down the smoke that poured from the kilns, making the pottery districts most insalubrious. But the major development was, as in other industries, to replace batch, or non-continuous, heating by continuous firing, as in the tunnel kiln. The first was built in Denmark in 1839 and, although not really satisfactory, its importance was recognized. Improvements followed and a kiln fired by producer gas was erected in 1873 and patented four years later. In 1878 a tunnel kiln was installed in London and the first in the USA was at Chicago in 1889.

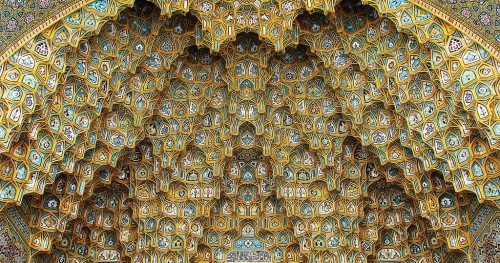

During the last half of the nineteenth century, the ceramics industry changed further into a science-based technology, as the materials used in the industry and the processes they underwent were subjected to systematic scientific examination. The credit for much of the pioneer work on the clays belongs to the chemist H.Seger. In the present century the range of ceramic materials and their application throughout industry has greatly widened. In fact over the last fifty years the traditional definition of ceramics as clay-based products has had to be abandoned. The term is now broadened to cover any inorganic substance which, when baked, attains the familiar rock-like hardness with other special characteristics. Silicon carbide is such a material, with important applications in the abrasive industry.

The Vital Role of Steel in Technological Development

The Vital Role of Steel in Technological Development